Formation of basalt

Basalt, mainly composed of oceanic crust, belongs to basic volcanic rocks. It is the most important component of the Earth’s oceanic crust and lunar sea, as well as an important component of the Earth’s continental crust and lunar land.

Basalt belongs to magmatic rocks in geological rock classification. The magma emitted by volcanic eruptions has a high temperature and a certain viscosity. During its flow, it carries a large amount of water vapor and bubbles. After cooling, it forms various variant shapes of basalt.

Main ingredients

The main components of basalt are silicon dioxide, aluminum trioxide, iron oxide, calcium oxide, magnesium oxide (with a small amount of potassium oxide and sodium oxide), with the highest content of silicon dioxide, accounting for about 45 to 50%.

Application

The color of basalt is commonly black, dark brown, or dark green. The texture is dense, and its specific gravity is heavier than that of ordinary granite, limestone, sandstone, and shale. However, some basalts have a particularly large number of pores, which reduces their weight and even allows them to float in water. We call this porous lightweight basalt “pumice”. Some artists, based on the porous, wrinkled, and leaky characteristics of pumice, use them to build rockeries in gardens or carve small and exquisite bonsai.

Pumice has many pores and is quite hard. Mixing it with concrete can reduce the weight of the concrete, but it is still very sturdy. It also has characteristics such as sound insulation and heat insulation, making it a material for lightweight concrete in high-rise buildings. Pumice is still a good grinding material, which can be used to grind metal and stone materials. It can also be used as a filter, dryer, catalyst, etc.

Basalt is also a good raw material for producing cast stones. Cast stone is a material made by melting, casting, crystallizing, and annealing basalt. It is harder and more wear-resistant than alloy steel, and more resistant to corrosion than lead and rubber. Basalt also acts as a lubricant in an advanced steel casting process, which can extend the lifespan of the casting film. At the same time, basalt can also be drawn into glass fibers, which have stronger alkali resistance and better high-temperature resistance than ordinary glass fiber cloth. Basalt can also be used as the main raw material for dark glazes such as yellow, red, and black.

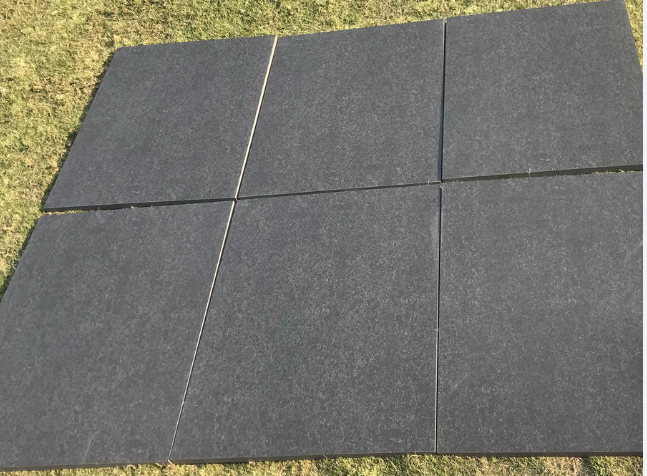

Last but not least, black basalt slab can be used for countertops or paving stone. The basalt is cut into size stones. Thin basalt slabs are cut and polished for use in building finishes, monuments, floor tiles, and other stone materials. Black Basalt Paving is a dark charcoal grey when dry and a solid black colour when wet. All sides are sawn and the top surface is flame textured.

LEESTE has 3 processing bases (Yunfu, Fujian, Yixing), LEESTE is the largest and the most advanced stone processing enterprise. So LEESTE can provide high quality black basalt slab products which are insuranced. Choosing anti slip black basalt slab for your interior design or architectural project can be an excellent decision,. If you have any queation, please contact us immediately!