A micro linear actuator is a small and precise electromechanical device used to convert rotary motion into linear motion. These devices are commonly employed in various applications where fine control of linear movement is required. Micro linear actuators are typically characterized by their compact size, low power consumption, and ability to move with high precision and accuracy.

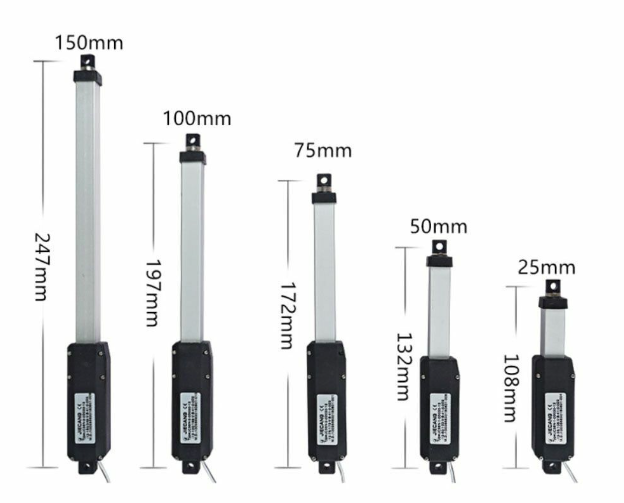

In simple language, micro linear actuators are essentially compact actuators with a limited range of motion. These tiny devices typically have strokes that range from a few millimeters to approximately 50mm. Due to their small size and restricted stroke length, they generate less force compared to regular linear actuators. This is because their power source, often a smaller motor, provides less force to the micro actuator.

Features of electric linear actuator

Miniature Size: Micro linear actuators are designed to be small in size, making them suitable for applications with limited space.

High Precision: These actuators offer precise and accurate control over linear movement, often with resolutions measured in micrometers.

Electrically Driven: Micro fast linear actuator is usually powered by electric motors, such as stepper motors or servo motors. They may also use piezoelectric elements for extremely precise movements.

Linear Motion Mechanisms: They employ various mechanisms to generate linear motion, such as lead screws, ball screws, belts, or pulleys.

Low Noise and Vibration: Many micro linear actuators are engineered to operate quietly and with minimal vibration, making them ideal for applications where noise is a concern.

Control Interfaces: Micro linear actuators can be controlled using various interfaces, including analog voltage signals, digital signals, or even through software using a microcontroller.

Where are micro linear actuators used?

Many people may not realize that technology encompasses anything that simplifies our lives. Whether it’s a pencil, a chair, or a supercomputer, they all fall under the umbrella of technology. We find ourselves in an era where technological advancements are occurring at such a rapid pace that it’s challenging to keep up with the breakthroughs happening in every field of science and engineering. It’s a thrilling time to be alive.

Did you know that approximately 45% of the tasks people are employed to do can be automated using current technology? A significant driving force behind the progress in automation technology is the recent evolution of micro linear actuators.

Linear actuators are uncomplicated yet essential components in any apparatus or machine, enabling movement in a straight line. The concept remains the same when it comes to micro linear actuators, just on a smaller scale.

If you’re eager to delve deeper into the world of actuators and wish to understand how to incorporate them into your upcoming projects, sit back and continue reading. We’re about to provide you with all the essential information to set your projects in motion using linear actuators.

So, how do a small linear actuator work?

The advent of linear actuators marked a watershed moment in our contemporary society, akin to the significance of the wheel in ancient civilizations. While advancements have certainly refined the original design, the fundamental principles governing the functionality of linear actuators have remained steadfast.

Among the most prevalent types of linear actuators utilized in automation are those driven by electricity. These electric actuators, propelled by AC/DC electric motors with varying stroke options, accomplish the transformation of rotary motion from an electric motor into linear motion along a straight path. They exhibit the capability to exert force both in a pushing and pulling manner.

To regulate the high-speed rotation of the motor, a multi-stage helical gearbox intervenes, effectively reducing the speed and concurrently enhancing the torque. This torque, in turn, sets in motion a lead screw, thereby engendering the linear motion through the action of a drive screw/nut mechanism. Altering the polarity of the motor serves as the means to reverse the direction of motion, thereby toggling between push and pull actions.

Check out all of our mini linear actuator options to find what you need and contact GUOYUAN ELECTRONICS for more imformation.