What is a thin film capacitor?

Thin film capacitors are a type of electronic component used in various electronic circuits to store and release electrical energy. These capacitors are characterized by their construction, which involves a thin film of conductive material deposited on an insulating substrate. The thin film acts as one of the capacitor’s plates, while the substrate serves as the other plate.

What is a thin ceramic capacitor?

A thin ceramic capacitor, sometimes referred to as a chip capacitor, is a type of electronic component that serves as a passive component in electronic circuits. It is constructed using ceramic materials and is known for its compact size and versatility.

Film capacitors and ceramic capacitors are two common types of capacitors used in electronic circuits, and they have distinct characteristics. Here are the key differences between them:

Dielectric Material:

Film Capacitors: Film capacitors use a thin plastic or polymer film as the dielectric material. Common dielectric materials for film capacitors include polyester (Mylar), polypropylene, and polyethylene terephthalate (PET).

Ceramic Capacitors: Ceramic capacitors use ceramic materials as the dielectric. These ceramics vary, but common types include X7R, Y5V, and NPO ceramic dielectrics.

Capacitance Values:

Film Capacitors: Film capacitors tend to have higher capacitance values, typically ranging from picofarads (pF) to microfarads (µF).

Ceramic Capacitors: Ceramic capacitors generally have lower capacitance values, usually in the range of picofarads (pF) to nanofarads (nF). They are typically not used for high capacitance values.

Tolerance:

Film Capacitors: Film capacitors often have a higher tolerance, meaning their actual capacitance value is closer to the specified value. They are suitable for applications requiring precise capacitance values.

Ceramic Capacitors: Ceramic capacitors can have a wider tolerance range, and their actual capacitance value may vary more from the specified value. This makes them suitable for applications where precise capacitance is less critical.

Temperature Stability:

Film Capacitors: Film capacitors generally exhibit good temperature stability, with minimal changes in capacitance over a wide temperature range.

Ceramic Capacitors: The temperature stability of ceramic capacitors can vary depending on the type of ceramic dielectric used. Some ceramics, like NPO, offer excellent stability, while others, like Y5V, exhibit more significant variations with temperature.

Frequency Response:

Film Capacitors: Film capacitors are suitable for a broad range of frequencies, making them ideal for high frequency and audio applications.

Ceramic Capacitors: Ceramic capacitors are also used in various applications but may exhibit some nonlinearity in their capacitance with changing frequency.

Voltage Ratings:

Film Capacitors: Film capacitors often have higher voltage ratings, making them suitable for applications where higher voltage requirements are necessary.

Ceramic Capacitors: Ceramic capacitors come in various voltage ratings, but they may be limited in high voltage applications compared to film capacitors.

Size and Form Factor:

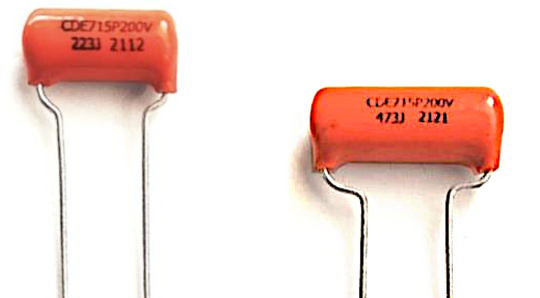

Film Capacitors: Film capacitors tend to be larger in physical size compared to ceramic capacitors.

Ceramic Capacitors: Ceramic capacitors are compact and come in various form factors, including surface mount types.

The choice between film capacitors and ceramic capacitors depends on the specific requirements of the electronic circuit, including capacitance value, tolerance, temperature stability, and other factors. Both types have their strengths and are used in a wide range of applications in the electronics industry.

What are the advantages of film capacitors?

Film capacitors are widely used because of their superior characteristics. Film capacitors have a long shelf and service life, and are very reliable, with a very low average failure rate. They have low ESR (Equivalent Series Resistance), low self-inductance (ESL), and as a result very low dissipation factors.

Power film capacitors are used in power electronics devices, phase shifters, X-ray flashes and pulsed lasers, while the low power variants are used as decoupling capacitors, filters and in A/D convertors. Check out all of our film capacitors options to find what you need and contact GUOYUAN ELECTRONICS for more imformation.